Introducing PVQ 4.0 - Learn more about the magic now

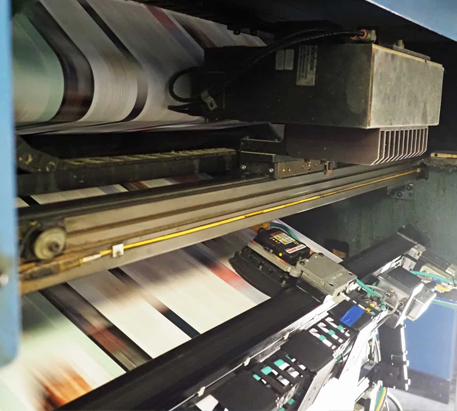

Fueled by 100 years of innovation, Baldwin Technology provides the top hardware, software and consumables to automate, enhance and apply intelligence to production processes. We specialize in engineering & manufacturing solutions for printing, packaging & converting, textile production, film extrusion, and other industrial applications.

Our leading brands include AMS Spectral UV, Ahlbrandt, Baldwin Vision Systems, Primarc and Western Quartz.

CHECK OUT THE LATEST NEWS FROM BALDWIN TECHNOLOGY:

Battery Technology Online highlights the Electrode Press Industrial Cleaning (EPIC) System by Baldwin, the world’s first in-line cleaner for non-stop production of advanced battery foils.

Building on its groundbreaking partnership with Monforts and Archroma, Baldwin Technology, a brand of BW Converting, will empower textile manufacturers to take the lead in sustainable finishing with its TexCoat™ G4 precision spray system at ITMA Asia 2024.

At this year’s SuperCorrExpo, Baldwin team members had the pleasure of being interviewed by INKISH to talk about FlexoCleanerBrush - a fully automated flexo plate-cleaning system that can be up to 126 inches (3.2 meters) wide.

In the precision-critical world of printing, ensuring complete accuracy for labels – especially in the pharmaceutical sector – is paramount, Pragati faced the challenge of manual offline inspection processes that were not only time-consuming, but also prone to human errors.

I.D. Images’ investment in BW Converting’s cutting-edge Baldwin Guardian PQV 100% inspection system immediately paid for itself with the very first job. Over the past eight years, the technology has saved the company, a leader in stock and custom label solutions, hundreds of thousands of dollars.

The integration of BW Converting’s Baldwin Color Control System (CCS) with System Brunner's Instrument Flight color evaluation software has evolved in step with the changing demands of commercial web offset printers for more than two decades.

Baldwin Technology is showcasing its newest breakthroughs in printing technology at DRUPA 2024, from May 28 to June 7 in Düsseldorf, Germany, Hall 16/Booth D20 & C21.

Pincroft, a leading textile dyeing, printing and finishing company, bolstered its efforts to achieve efficient and sustainable textile operations by adopting Baldwin Technology’s innovative TexCoat™ G4 system.

Now an industry leader with zero-defect printing, Winpak redefines packaging standards through integration of Baldwin's advanced inspection systems.

In the concluding part of our round table series, we delve into how the paper shortage crisis sparked flexibility and creativity within the industry, ultimately leading to innovative applications and opportunities for cost savings.

Baldwin will join Elamtex GmbH at Techtexil to demonstrate how its revolutionary TexCoat G4 precision spray finishing system eliminates chemistry waste on changeover, saves water and achieves faster speeds through the stenter frame.

Baldwin’s advanced corrugated technologies including FlexoCleanerBrush™ and FlexoDry were highlighted in the spring issue of International Paper Board Industry North America.

In the second part of this round table, we delve deeper into the industry's dedication to minimizing its environmental impact and the increasing significance of transparency and sustainability within the supply chain.

Rick Baldwin recently sat down with Kohan Textile Journal on the topic of navigating Asian markets, expanding frontiers, and innovating in the marketplace.

In today's dynamic business landscape, adaptability is key to survival. The printing industry, known for its resilience and evolution, recently faced an unprecedented and formidable challenge with a worldwide paper shortage.

Baldwin’s conventional UV, LED-UV, and IR systems were highlighted in this month’s issue of PFFC.

Patrick Keller recently had the opportunity to talk to WhatTheyThink! magazine about the history of Baldwin and its broad set of solutions for a vast array of industries, including many aspects of print.

Baldwin Technology Co. Inc. continues to invest in resources and manufacturing capabilities to meet growing demand across multiple print, packaging and industrial markets in the Americas.

Baldwin’s Kevin Joesel, Industrial Sales Executive for the Americas, had the pleasure of speaking with Jeff Peterson from UV+EB Technology Magazine at this year’s ICEC USA conference in Orlando, FL.

First Koenig & Bauer Rapida 106X Double Coater Perfector UV press in U.S is also world-first configured with Baldwin's PREPAC®,automatic blanket cleaning system

Baldwin’s offset printing technology was recently featured in Deutscher Drucker magazine. Learn how MultiCam was used by B&K Offsetdruck, one of the highest-profile web offset printers in Germany.

Baldwin’s corona treatment technology was highlighted in the December 2023 issue of PFFC.

Maharshi Labels PVT. LTD. , a renowned global leader in the printing and packaging industry, recently installed Baldwin Technology Co. Inc.’s cutting-edge Guardian OLP Offline Proofing and Inspection system (OLP).

Baldwin Technology Company Inc. will be educating the textile supply chain on how to “Start with Baldwin and Finish with Perfection” thanks to its TexCoat™ G4 precision spray finishing system at ITMA Asia 2023.

Baldwin will be demonstrating its corrugated-industry leadership by sharing a “Diamond Standard” on cleaning and drying revelations at the forthcoming FEFCO Technical Seminar

Baldwin Technology Company Inc. will highlight the level of perfection achievable with its inspection and LED technologies for narrow and wide web print at the FTA Fall Technical Conference with Infoflex.

Baldwin Technology will showcase its award-winning X Series™ line of LED UV curing solutions at the 2023 Tape & Functional Film Expo, taking place in Detroit, Michigan, from October 4-5.

Paper Converting Machine Company (PCMC), Baldwin Technology Co., and Winkler + Dünnebier (W+D) will be making their formal launch as BW Converting Solutions at PRINTING United Expo in Atlanta.

Rudolf GmbH, a leading provider of chemicals to the textile industry, can now offer side-by-side performance tests of the age-old “dip and squeeze” pad versus precision spray finishing with the delivery of Baldwin Technology Inc.’s TexCoat ™ G4 lab-scale unit.

“Working with Baldwin we had no difficulties at all, from point of order to installation … and the after-service is brilliant.”

- Ian Jones, Welshpool Printing Group (United Kingdom)

Why partner with Baldwin?

Premium technology

Unmatched process support

IoT-connected solutions

Friendly field service

Fast and reliable parts ordering

Global presence and availability

Tailored support

100 years of continuous innovation